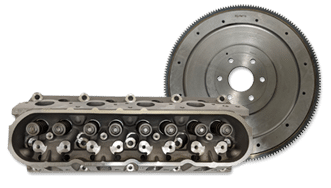

Prepping Cylinder Head

TRANSCRIPTION

When prepping the head, we spray this down with a water solution soap cleaner. This is so that we can get all of the debris or anything that is left on the head, off. Now we’re blowing out the head and drying off the solution, and blowing the holes so if there is anything impacted at the bottom of the holes, it will come loose, and at this point we are also looking to see if there are any broken or damaged areas on the head before we go to the next step.

The head is now flipped over and what we are going to do is work in the combustion area for the guides. Now we are spraying the guides and the surfaces to remove any Cosmoline or any type of sealer from the surfaces so its nice and clean. Get the air nozzle, blow off the head, blow into the water ports, so if there are any aluminum chips, they all come clean and out of the water jacket area. Guides are going to be sprayed with the soapy solution, as you will see, and also right after this, what will happen is all of the guides will be brushed. After the completion of brushing all of the guides, as each and every guide will get brushed with the proper brush so it’s cleaning every single guide out, then it will be blown again with the air gun.

Spray it down one more time overall and blow until the head is dry and clean.

Watch for part 2 on this video as the head gets moved to the clean room for assembly.